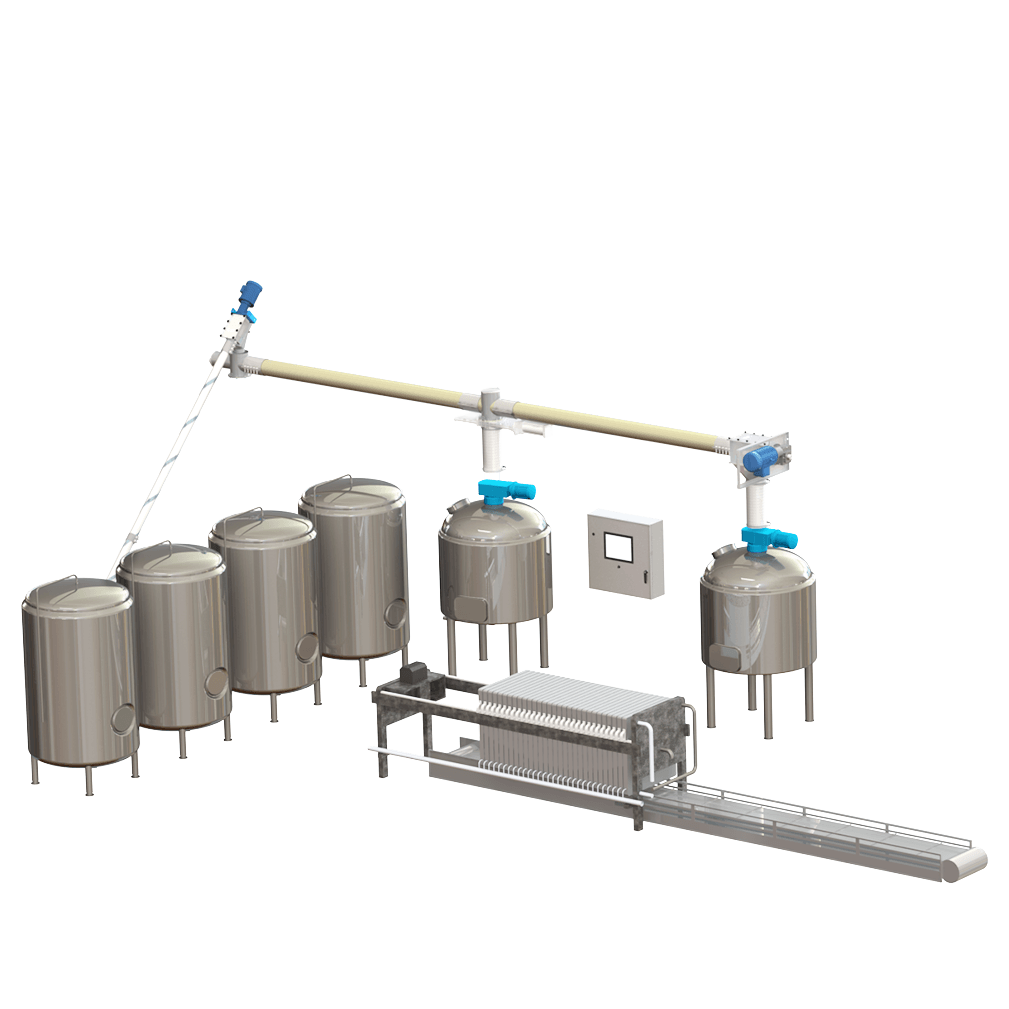

A variety of methods can be used for mixing, blending, and steeping coffee. We offer systems and tanks for processing 30 gallons per batch up to 1,000+ gallons per batch. Immersion, Kyoto/Dutch cold drip, or agitation processes available

Cold Brew Extraction Systems

Combined with a mixing / blending tank, Lotus filter presses systems are ideal for high volume coffee beverage processing:

- Touchscreen control systems

- Steam or electric heating

- Glycol chillers + heat exchangers

- False bottom tanks for ground separation

- Filter press technology to get the most out of your brew

- We offer several techniques for final filtration: bag filters, cartridge filters, and plate filters

Material Handling

We offer material handling solutions for all sizes of coffee beverage production facilities. Fully integrated bulk bag unloaders, storage silos & bins, feed augers, and chain conveyors. For large production facilities we also offer spent ground disposal systems that include pelletizing for secondary markets:

- Equipment options are forklift ready and made for bulk storage totes

- Loss-in-weight bulk unloader to meter biomass from totes in preset batch size

Steeping Vessels

Our tanks can be custom sized and designed to fit your application and requirements, including jacketed tanks, heated tanks, mixing tanks, and ASME pressure rated tanks:

- Integrated, removable stainless steel filtration screens (50 micron, other sizes available)

- Dish bottom and lid with retaining bar

- Side manway for easy removal of coffee grounds

- Spray ball under false bottom

- Outlet above the false bottom for recirculation

- Wide variety of sizes available from 30 gallons to 200 barrels

- Available in 316 or 304 stainless steel

- Customization options include port locations and glycol piping

Nitrogenation & Storage Vessels

Cold storage is imperative to maintain cold chain requirements when it comes to craft coffee production. We offer jacketed tanks from 1/2 to 120+ barrels:

- Jacketed brite tanks allow you to precisely control the temperature

- Non-jacketed tanks allow you to store your brite tanks right in your cold room

- CIP arm spray balls for easy cleaning

- Available in 316 and 304 stainless steel for easy cleaning

Controls

Our control panel designs have evolved over years to incorporate more features and functionality:

- Configurations include advanced touchscreens or basic switches, buttons and dials

- Tailor your automation to your process. Our engineers create custom control panels that fit your needs

- Monitor and control your process from ingredient handling, heating and cooling systems to pumps and sanitation or any other process

- Our panels are UL (for the US) and cUL (for Canada) listed as an assembly. Each panel has its own unique UL listing number assigned to it that is typically required by your electric inspector to obtain a certificate of occupancy

Designed through

coffee creator feedback

Our best features come from our customers. Frankly, they have been designed, tweaked, advanced and improved by you.